Basic Info

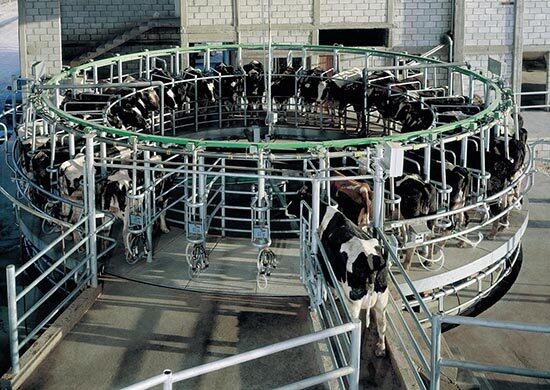

A high-efficiency group milking system where cows stand on a slowly rotating circular platform.It is designed for large-scale dairy farms to significantly increase milking efficiency per operator.

Customer reviews

Dr. Ben Carter · Resident Veterinarian

Its dustproof and waterproof design is fully adapted to the barn environment. The early pregnancy diagnosis (at 28 days) accuracy exceeds 95%. Combined with the rectal probe, we can efficiently monitor the herd's ovarian synchronization protocols, doubling our reproductive management efficiency.

Camilla Rossi · Environmental Control Engineer

After installing 32 of your tunnel fans throughout our finishing barns, the pigs' respiratory rates dropped significantly during summer. I'm most impressed with the motors' IP55 rating—after two years in a high-humidity, high-ammonia environment, there has been no corrosion or insulation failure, and the energy consumption data perfectly matches the technical manual specifications.

Sarah Benson · Operations Manager

The temperature control stability of our new single-stage incubators exceeded expectations. Even at full capacity, temperature variance across the cabinet remained within ±0.15°C, which is critical for chick uniformity. The integrated remote alarm system once provided timely warning of a water pressure anomaly, preventing a potential loss.

Product Description

Product Features:

The core advantage of a rotary parlor is its assembly-line efficiency.The rotating design allows for clear task division(prepping,attaching clusters,post-dipping)in a steady rhythm.Integrated ACR systems detach clusters when milk flow drops below a set threshold,preventing over-milking and promoting udder health.Data such as cow ID,yield,milking duration,and udder health conductivity is captured in real-time and uploaded to management software for precise herd management.The platform is designed for cow comfort and safety,minimizing stress.

Product Specifications:

A 40-stall rotary system has a diameter of approximately 20 meters.It is powered by a high-capacity central vacuum unit with a stabilization system for consistent vacuum at each point.Each stall has an independent pulsator(typically 4-phase),a milk meter,and sensors.An automatic Clean-in-Place(CIP)system cleans all milk-contact piping.The control cabinet with a human-machine interface monitors rotation,vacuum,equipment status,and cow data.Installation requires a holding area,exit lanes,and bulk milk cooling tanks.

Product Applications:

Used on large-scale dairy farms with 500+cows,targeting high efficiency and data-driven management.Cows enter the rotating platform from a holding area.Operators at the entrance perform teat cleaning and cluster attachment.Milking occurs during rotation,with automatic detachment and teat dipping before the exit,after which cows walk off.This system can increase a single operator's throughput to over 70-100 cows per hour,significantly reducing labor costs while improving herd health and management through standardized procedures and real-time data.

Frequently Asked Questions (FAQ)

Q:How does the automatic washing (CIP) system of a rotary milking parlor work?

A:After milking, the system automatically runs a preset program: first rinsing pipes with warm water, then circulating a hot alkaline detergent, followed by an acidic solution to neutralize and sanitize. This ensures all milk-contact surfaces are clean and sterile in a fully automated process.

Q:How many operators does a rotary milking parlor require?

A:Typically 1-2. One person guides cows onto the platform and performs pre/post-dipping, another patrols cups and observes. Highly automated systems can be operated by one person, with efficiency depending on rotation speed.

Q:How to ensure hygiene and milk quality during milking?

A:Relies on programmable automatic cleaning (CIP) programs. After each milking, the system automatically circulates hot water above 85°C and acid/alkaline solutions through all milk lines, teat cups, and vacuum lines.

Q:Why is vacuum system stability important?

A:Stable vacuum (42-50kPa) is key for gentle, efficient milking. Excessive fluctuation can cause incomplete milking or udder damage. Choose a central vacuum pump with high flow rate and a stabilizer tank.

Q:What scale of farm is it suitable for?

A:Suitable for large-scale dairy farms with over 300 cows. Its high investment needs to be recouped through economies of scale. A 48-stall rotary can process 150-200 cows per hour, fitting a 2-3 times daily milking rhythm.

Q:What daily maintenance is required?

A:Daily checks of teat cup liners, pulse tubes, and vacuum gauges. Weekly checks of vacuum pump oil level and belt tension. Monthly cleaning of the vacuum stabilizer tank and checking pulsation frequency.

Post RFQ

Post RFQ

Post RFQ

Post RFQ