Basic Info

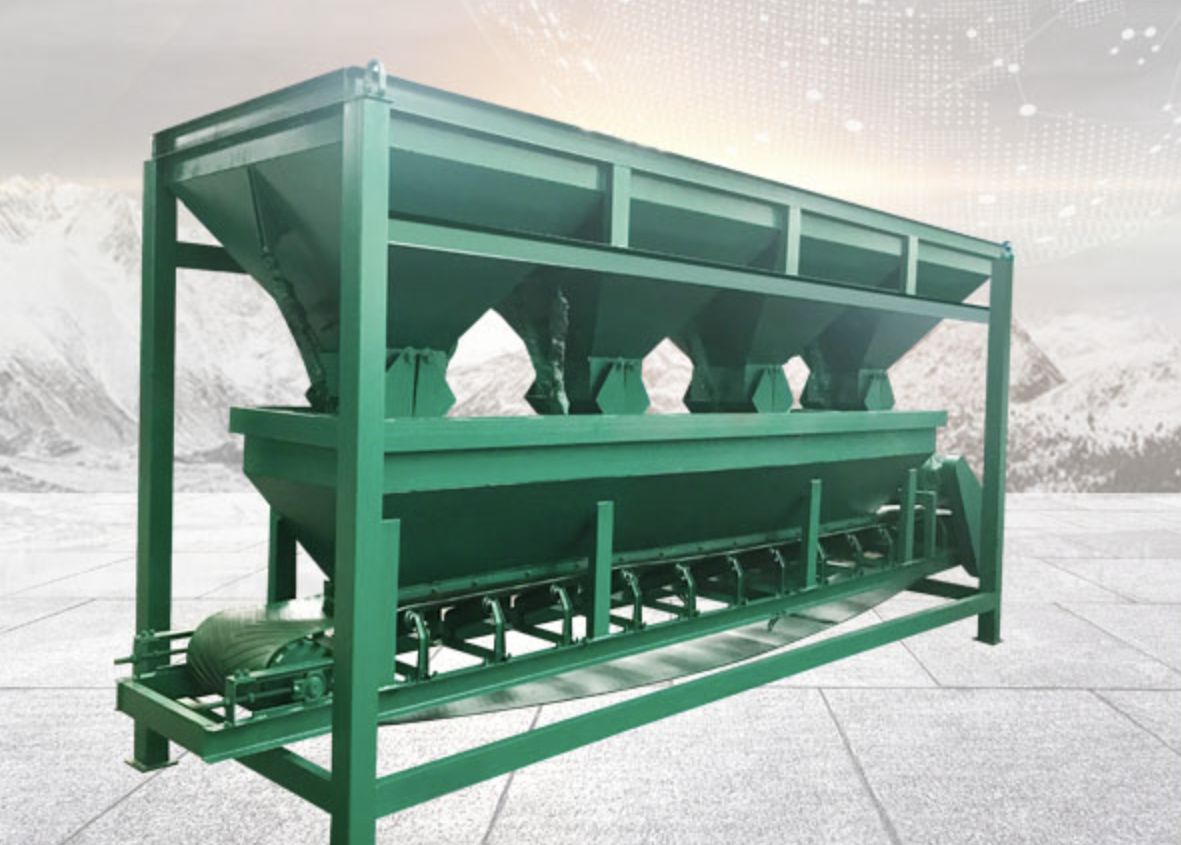

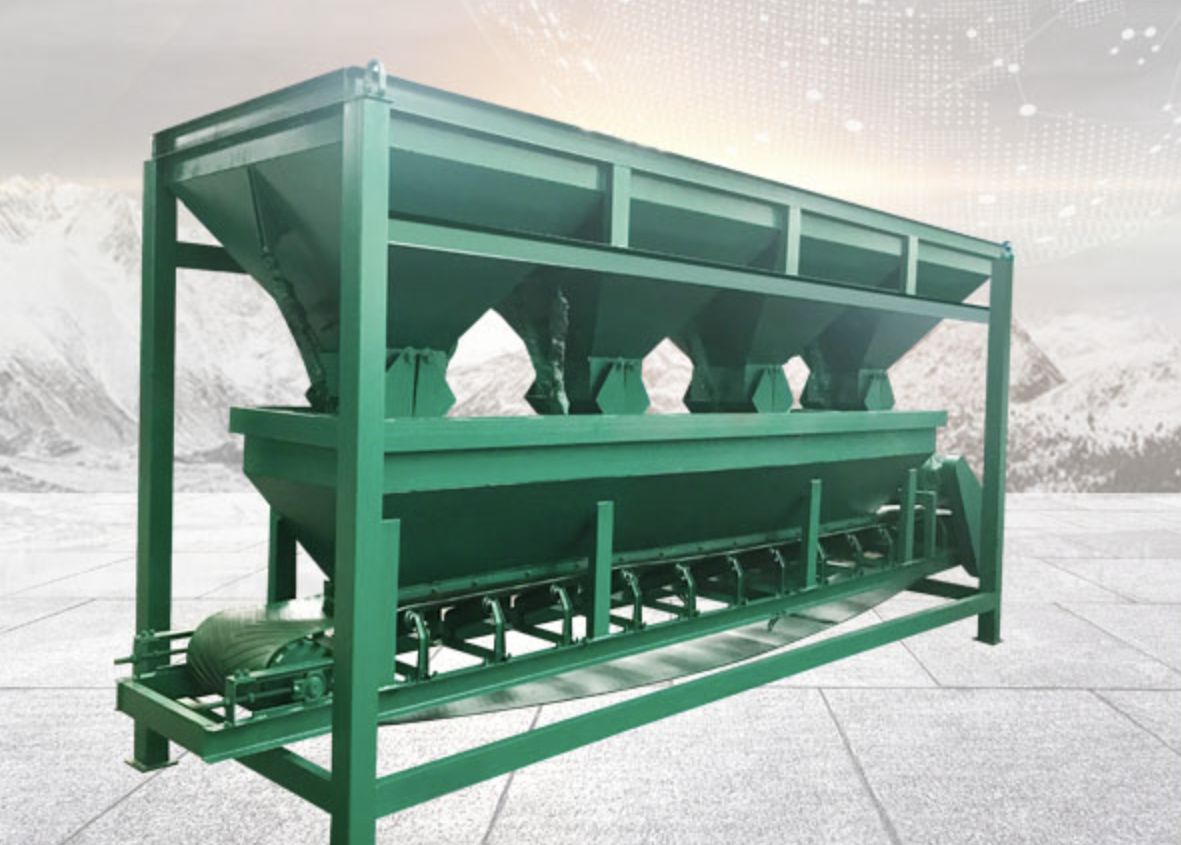

A device that achieves precise mixing of fertilizer raw materials via automated weighing and dynamic proportion adjustment. It is a core device for compound fertilizer and BB fertilizer production lines, ensuring uniform nutrient ratios and improving product quality stability.

Customer reviews

Aurora Perez · Process Technician

"Stainless steel contact components adapt to water-soluble fertilizer batching with good corrosion resistance. The cleaning process could be more automated."

Leo Foster · Procurement Officer

The horizontal mixer resolves our multi-raw material mixing unevenness problem. It mixes various fertilizer raw materials thoroughly and evenly, ensuring stable and consistent efficacy of finished fertilizers and avoiding local nutrient deficiency. Moderate mixing force won’t damage raw material properties, runs stably with low noise, has suitable capacity for mass production and is easy to clean without residue. High cost-performance and thoughtful after-sales service make it a reliable helper in fertilizer batching.

Lucas Perez · Farm Operations Lead

"The automatic bacteria spraying device improves fermentation efficiency, keeping material oxygen content at 16%. However, diesel fuel consumption is 5% higher than expected; optimize the power system."

Product Description

Product Features:

High batching accuracy (error ≤±0.5%) to ensure uniform fertilizer nutrients; stores 100 formula groups for one-click capacity switching; 24/7 continuous operation, increasing production efficiency by 30%; modular design allows bin expansion (max. 8 bins); dust-sealed design meets environmental protection requirements; fault warning function reduces downtime risks.

Product Specifications:

Typical model (4-bin dynamic batching machine): Processing capacity 15t/h, accuracy ±0.5%, bin volume 1.5m³/bin, motor power 7.5kW, load cell range 500kg, dimension 5.2×2.8×3.5m; customizable stainless steel contact components (for water-soluble fertilizers) and explosion-proof configurations.

Product Applications:

Used for precise proportioning of NPK raw materials in compound fertilizers; blending of multi-element BB fertilizers; mixing of organic and inorganic fertilizers; customized formula production of water-soluble and slow-release fertilizers; compatible with small-to-medium fertilizer plants and agricultural material enterprises’ custom fertilizer production lines.

Frequently Asked Questions (FAQ)

Q:What is the batching accuracy of the automatic batching machine?

A:The batching accuracy is ±0.5%, which can ensure the uniformity of fertilizer nutrients and meet the national standard requirements of compound fertilizers and BB fertilizers.

Q:How many bins can the batching machine be customized with?

A:The number of batching bins can be customized from 2 to 8, which can meet the batching needs of different formulas, such as NPK compound fertilizer, organic-inorganic compound fertilizer, and slow-release fertilizer.

Q:Can the batching machine store multiple formulas?

A:Yes. The machine can store up to 100 groups of formulas. It can realize one-click formula switching, which is suitable for small-batch and multi-variety fertilizer production.

Q:What is the difference between belt conveying and screw conveying?

A:Belt conveying is suitable for granular materials with large particle size and good fluidity; screw conveying is suitable for powdery materials, with good sealing performance and no material leakage.

Q:Can the batching machine be connected to the production line for data networking?

A:Yes. The machine is equipped with RS485/Ethernet data interface, which can be connected to the upper computer system to realize real-time monitoring, data recording, and traceability of the batching process.

Q:Is the batching machine suitable for water-soluble fertilizer production?

A:Yes. The contact parts of the batching machine can be made of 304 stainless steel, with good corrosion resistance, which can avoid material pollution and is suitable for the batching of water-soluble fertilizer raw materials.

Post RFQ

Post RFQ

Post RFQ

Post RFQ