Basic Info

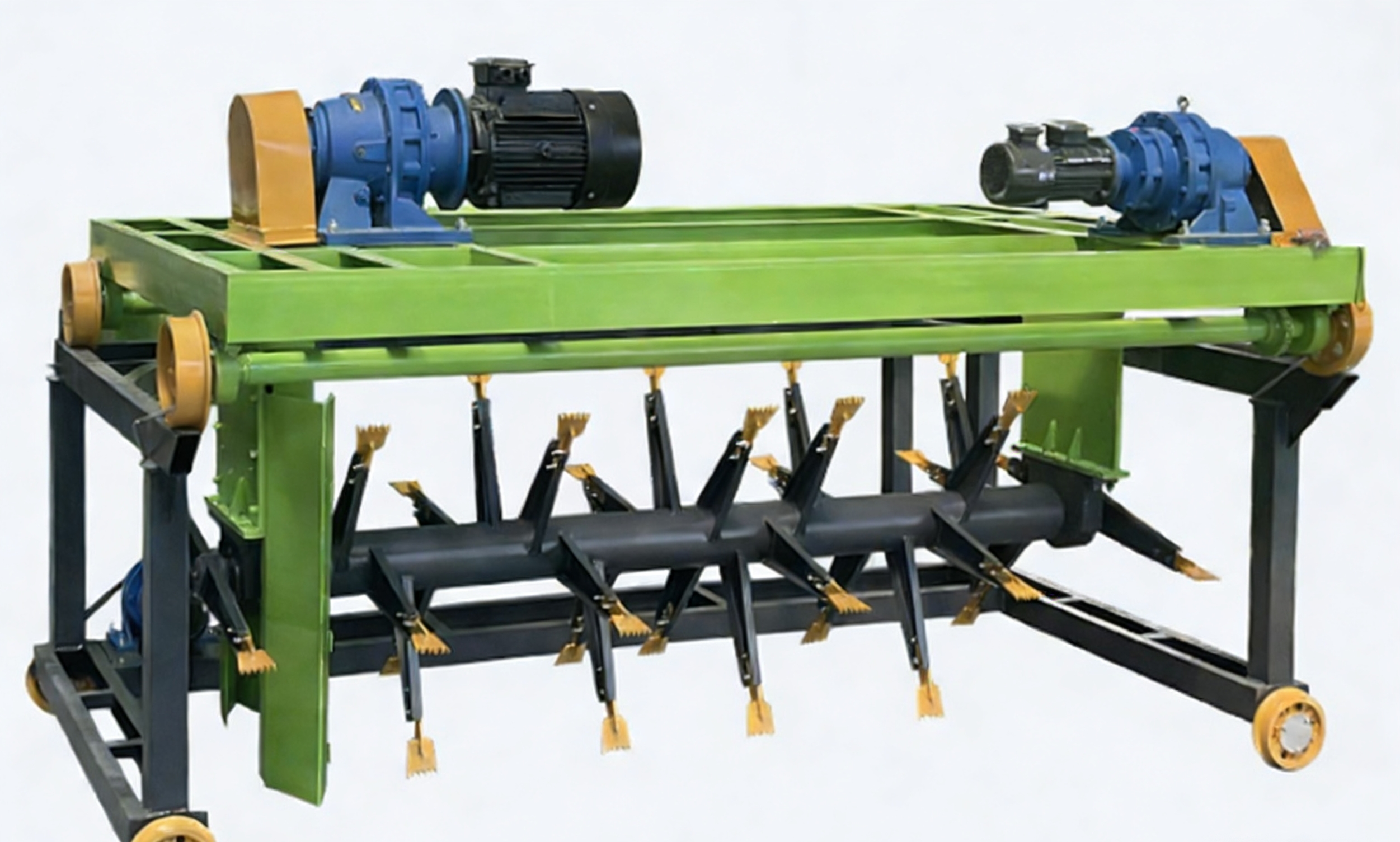

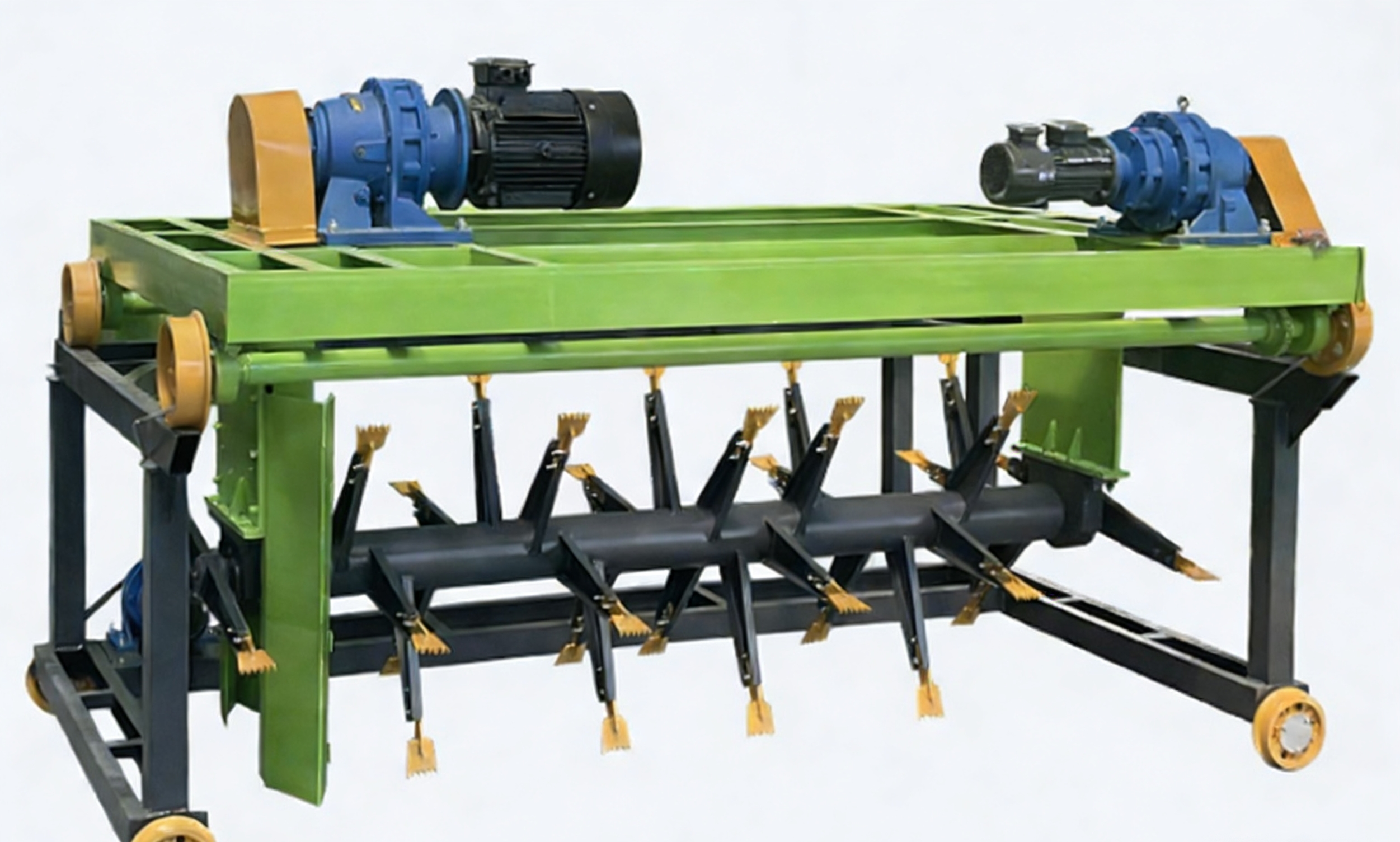

A core device for organic fertilizer production, it aerates materials and controls temperature via turning to promote microbial decomposition and fermentation. It is suitable for preprocessing organic raw materials (e.g., livestock manure, straw) and is key to the harmless and resourceful treatment of organic fertilizers.

Customer reviews

Aurora Perez · Process Technician

"Stainless steel contact components adapt to water-soluble fertilizer batching with good corrosion resistance. The cleaning process could be more automated."

Leo Foster · Procurement Officer

The horizontal mixer resolves our multi-raw material mixing unevenness problem. It mixes various fertilizer raw materials thoroughly and evenly, ensuring stable and consistent efficacy of finished fertilizers and avoiding local nutrient deficiency. Moderate mixing force won’t damage raw material properties, runs stably with low noise, has suitable capacity for mass production and is easy to clean without residue. High cost-performance and thoughtful after-sales service make it a reliable helper in fertilizer batching.

Lucas Perez · Farm Operations Lead

"The automatic bacteria spraying device improves fermentation efficiency, keeping material oxygen content at 16%. However, diesel fuel consumption is 5% higher than expected; optimize the power system."

Product Description

Product Features:

Uniform turning depth (deviation ≤50mm) and sufficient aeration (material oxygen content ≥15%); wear-resistant shaft treatment (service life ≥5000h); can integrate automatic bacteria spraying systems to improve fermentation efficiency; ride-on operation reduces labor costs, with processing efficiency equivalent to 100 workers; compatible with viscous (chicken manure) and loose (straw) materials.

Product Specifications:

Typical model (HQ-FD 2800): Turning width 2800mm, height 1000–1300mm, capacity 800–1000m³/h, power 123hp diesel engine, dimension 4.1×2.65×3.2m; customizable turning width (max. 3000mm) and remote control function.

Product Applications:

Used for aerobic fermentation of livestock manure (chicken manure, cow dung); decomposition of straw and food waste; organic fertilizer conversion of sludge and furfural residue; compatible with large organic fertilizer plants and livestock farm manure treatment projects, and can also handle small fermentation piles in family farms.

Frequently Asked Questions (FAQ)

Q:What raw materials can the compost turner handle?

A:It can handle various organic raw materials, including livestock manure (chicken manure, cow dung), crop straw, kitchen waste, sludge, and furfural residue, to promote aerobic fermentation of materials.

Q:How does the turner improve the fermentation efficiency of organic fertilizers?

A:The turner can turn the material evenly, increase the oxygen content in the material (≥15%), adjust the fermentation temperature (control at 55–65℃), and accelerate the reproduction of microorganisms, thus shortening the fermentation cycle by 30%–50%.

Q:What is the difference between ride-on and remote control operation modes?

A:The ride-on mode is suitable for large-area fermentation yards, with high operation efficiency; the remote control mode is suitable for narrow spaces or harsh environments, which can avoid the operator being exposed to odor and dust.

Q:Can the turner be equipped with an automatic bacteria spraying device?

A:Yes. The optional automatic bacteria spraying device can evenly spray the fermentation strain on the material during turning, which improves the fermentation speed and the quality of organic fertilizer.

Q:What is the service life of the 65Mn steel cutter shaft?

A:The 65Mn steel cutter shaft is treated with quenching and tempering, with high wear resistance. Under normal operation conditions, the service life can reach more than 5000 hours, which is suitable for turning hard materials such as straw.

Q:Is the turner suitable for muddy fermentation sites?

A:Yes. The tracked compost turner has strong ground adaptability, large ground contact area, small ground pressure, and can operate normally in muddy and uneven sites.

Post RFQ

Post RFQ

Post RFQ

Post RFQ