Post RFQ

Post RFQ

Post RFQ

Post RFQ

EPDM's superior performance comes from its fully saturated rubber backbone. 1) Outstanding weather and UV resistance: can provide over 50 years of service life when directly exposed outdoors, with minimal performance degradation. 2) Excellent high and low-temperature performance: remains flexible at -45°C and does not flow at +120°C. 3) Superior elasticity and elongation: accommodates significant substrate movement and deformation, with an elastic recovery rate >90%. 4) Good chemical resistance: particularly resistant to weak acids, alkalis, salts, and polar chemicals. 5) High resistance to ozone and oxidation. 6) Environmentally safe and non-toxic, compliant with potable water standards. 7) Energy-efficient: lighter-colored products (special order) can reflect sunlight, reducing the heat island effect. 8) Can be manufactured as a pre-applied, loose-laid membrane for easier installation.

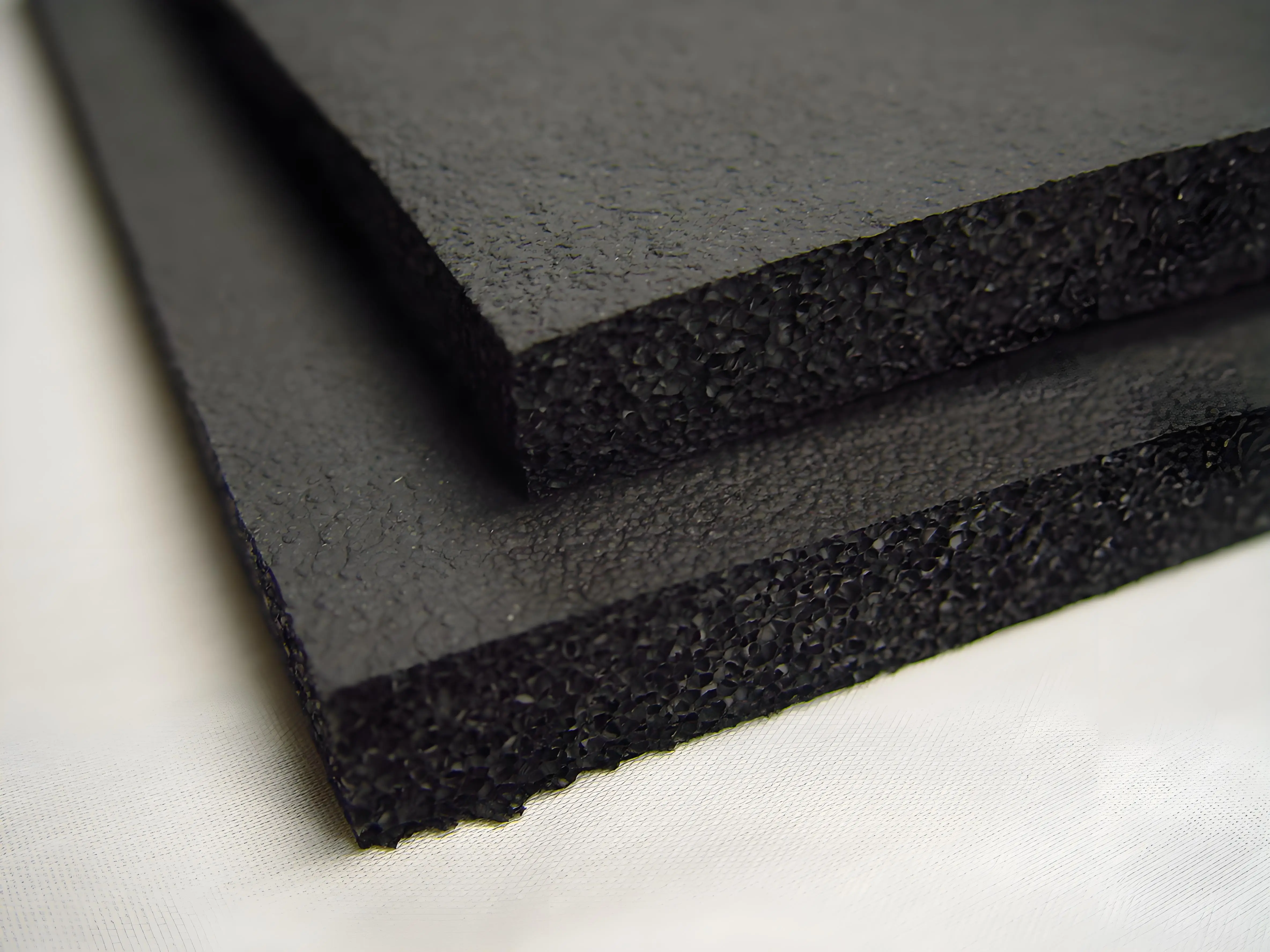

Standard widths are typically 3.05m, 6.1m, 9.15m, with lengths up to 61m (large rolls) to minimize seams. Technical indicators: 1) Uniform thickness with small tolerance. 2) High tensile tear resistance. 3) Good puncture resistance. 4) Excellent fatigue resistance, withstands repeated deformation. 5) Strong impermeability. 6) Fully vulcanized for long-term stability. 7) Good color stability, resistant to fading (black). 8) High peel strength with specialized seam tapes or adhesives (typically >25 N/cm). 9) Passes low-temperature flexibility test at -40°C. 10) Complies with international standards like ASTM D4637.

Suitable for applications demanding high durability and exposure: 1) Building roofing: waterproofing layer for flat roofs, green roofs, and roof gardens. 2) Landscape water bodies: permanent artificial lakes and golf course water hazards requiring high durability. 3) Municipal engineering: bridge deck waterproofing, culvert waterproofing. 4) Environmental engineering: long-term exposed covers for wastewater treatment tanks, biogas bags. 5) Water conservancy: liners for potable water reservoirs (using non-polluting formulations). 6) Sports facilities: waterproofing for stadium bleachers, base liners for artificial turf. 7) Industrial sector: covers for liquid storage tanks experiencing high temperatures or fluctuations. 8) Special vehicles: waterproof liners for containers.