Post RFQ

Post RFQ

Post RFQ

Post RFQ

Its mixing mechanism involves continuously dividing, redirecting, and recombining the material flow via the pins, achieving a good combination of distributive and dispersive mixing. It is particularly adept at handling high-viscosity, high-filler-load, or shear-sensitive materials. The clam-shell barrel design makes cleaning and color changes extremely convenient. Although structurally complex, its high mixing efficiency and relatively low energy consumption make it especially suitable for formulations requiring excellent dispersion.

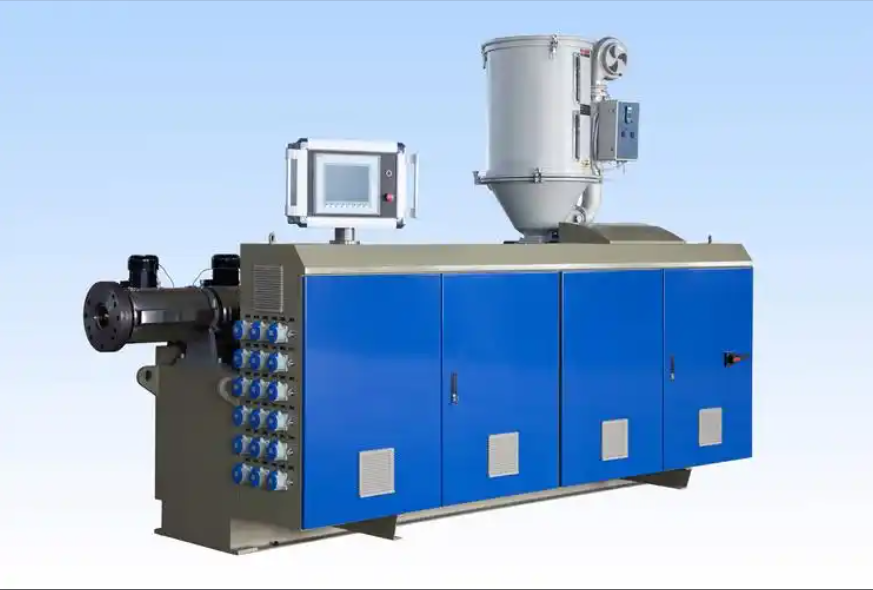

The core consists of a rotor with special helical channels and a matching clam-shell stator (barrel). The drive system includes a main motor for rotation and a hydraulic or servo system for reciprocation. The barrel inner wall is embedded with multiple rows of hard alloy pins. The temperature control system is robust to quickly remove heat generated by intensive mixing. It is typically equipped with a hydraulically driven screw extraction device for quick barrel opening and maintenance.

Widely used in fields requiring high-quality dispersive mixing, such as producing high-concentration color masterbatches (especially white and black), high-filler masterbatches (e.g., calcium carbonate, barium sulfate), cable compounds (insulation, sheathing), silane-crosslinked polyethylene, hot melt adhesives, sealants, and various plastic alloys and modified products. It also has unique applications in the gelation (plastisol making) of PVC paste resin.