Post RFQ

Post RFQ

Post RFQ

Post RFQ

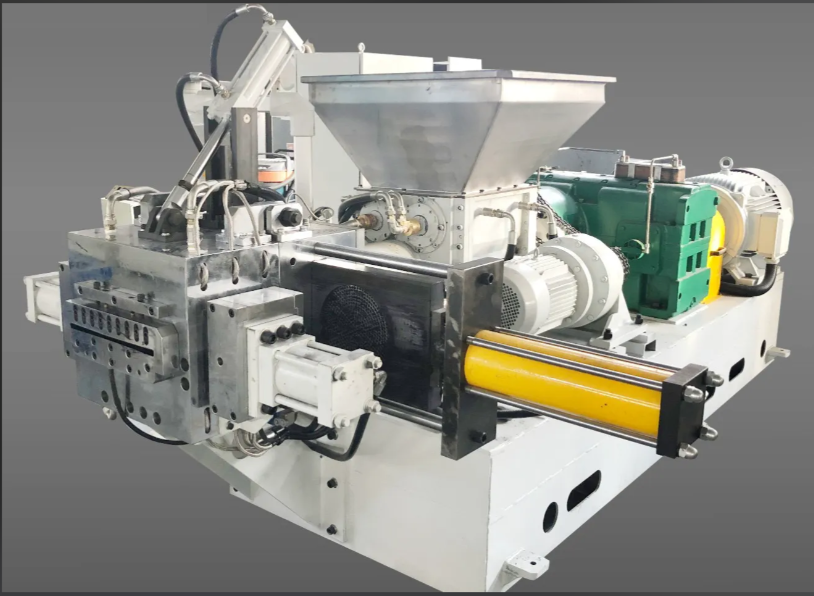

The primary characteristic is its ability to directly process cold, stiff rubber compound. Through long L/D and high-power design, it utilizes the compound's own viscous heat generation and external heating in the screw's conveying and shear zones to complete plastication and homogenization during extrusion. Forced feed rolls ensure the compound is forcibly and continuously bitten into the screw. The equipment requires extremely high rigidity to withstand massive head pressure. Temperature control must be precise to prevent compound scorching.

Screw design is complex, typically divided into feed, plastication (intense shear zone), and homogenizing/extrusion sections. The barrel has a double-jacket structure with a wear-resistant inner liner; the jacket can circulate steam for heating or water for cooling. It is equipped with a heavy-duty gearbox and thrust bearing assembly to withstand enormous axial forces. The control system must precisely monitor zone temperatures, screw speed, and motor load, with emergency stop and overload protection.

Mainly used for extruding semi-finished products for various rubber goods. In the tire industry, for extruding treads, sidewalls, and apex strips; in the hose industry, for extruding inner tubes and outer covers; also for manufacturing automotive seals, rubber profiles, cable sheathing, shoe sole strips, and various solid or microcellular rubber products. It is a key bridging equipment between mixing and forming in rubber processing.