Post RFQ

Post RFQ

Post RFQ

Post RFQ

Extremely high dimensional accuracy and stiffness stability ensure consistent slot/kerf width and sidewall perpendicularity. Requires extremely stringent machine spindle radial and axial runout tolerance (often <0.002mm). Kerf is极小 (接近ing wheel thickness), maximizing material savings on expensive stock.

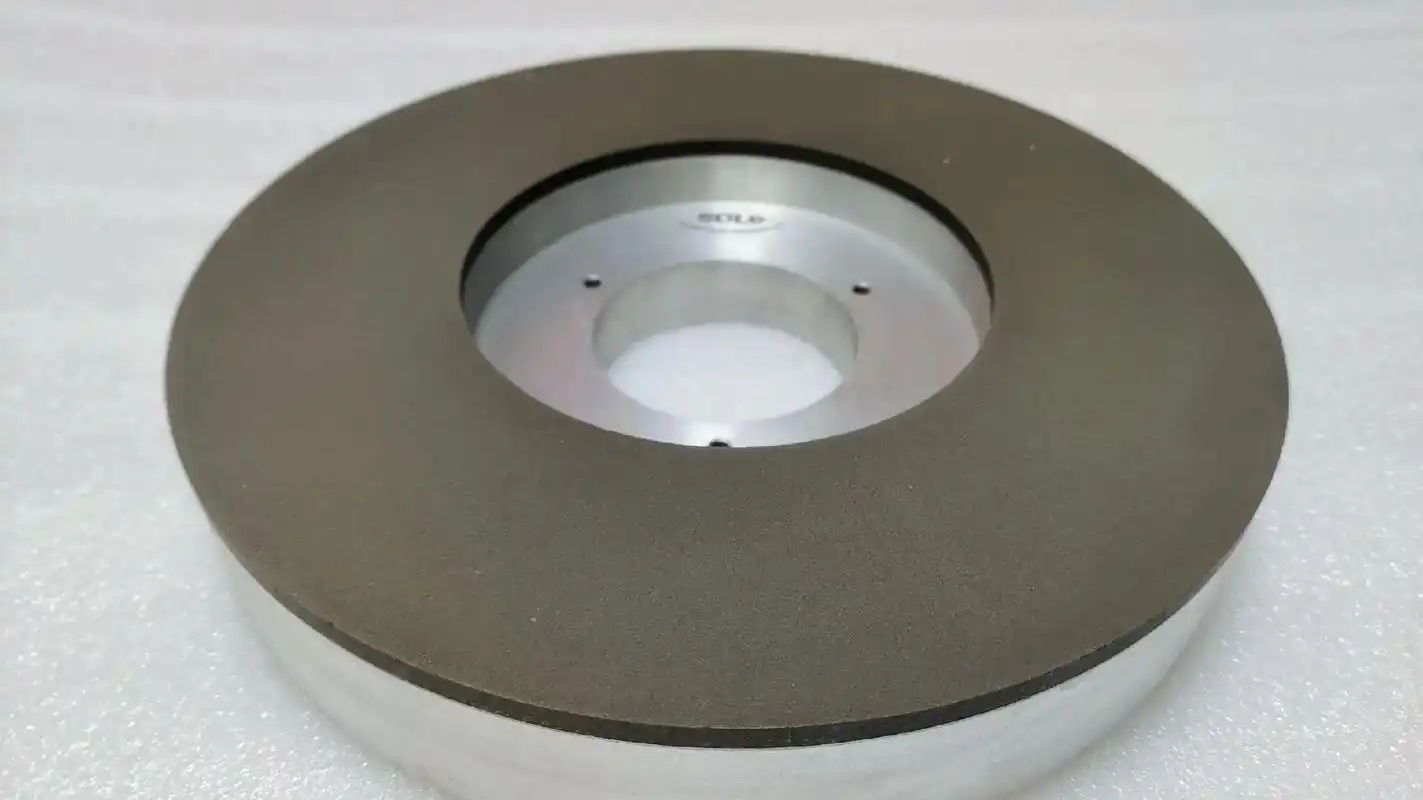

Diameters range from small 20mm dicing blades to over 200mm OD cutting wheels. Thickness can be as precise as 0.1mm. Abrasive is selected based on workpiece: diamond (hard/brittle) or CBN/alumina (metal). Resin wheels are common for precision cutting; metal-hub wheels for high-rigidity slot grinding.

Dicing and cutting of semiconductor wafers (Si, GaAs, Sapphire). Slicing of magnetic materials (NdFeB, Ferrite). Cutting of精密 ceramic substrates, gemstones. Flute grinding of carbide end mills, drills. Narrow slot and corner cleaning in precision molds (stamping dies).