Post RFQ

Post RFQ

Post RFQ

Post RFQ

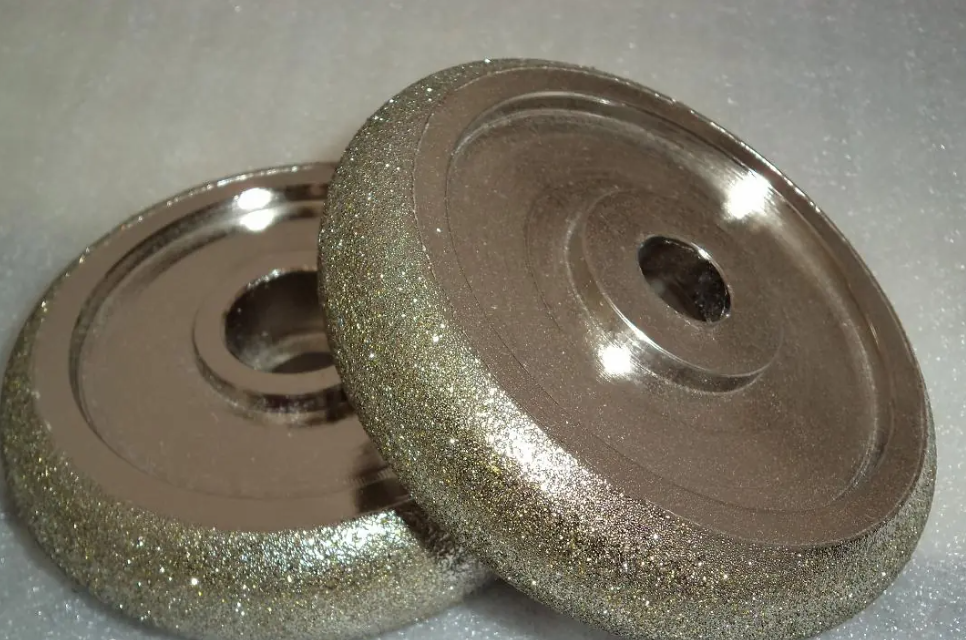

Hardness and wear resistance, resulting in a very high G-ratio (workpiece volume removed/wheel volume worn). Cuts sharply with high efficiency. Different bonds (resin, metal, vitrified, electroplated) cater to needs from rough grinding to mirror polishing. STRICTLY PROHIBITED for grinding ferrous/iron-based metals due to chemical wear (graphitization) at high temperatures.

Structure similar to CBN wheels. Resin bond (B) wheels are elastic and yield high finishes; metal bond (M) is most wear-resistant; vitrified bond (V) offers balanced performance; electroplated wheels are sharpest but shortest-lived. Concentration is a key parameter, from low (polishing) to high (heavy grinding).

Form grinding, slotting, and sharpening of carbide (tungsten) tools. Cutting and grinding of sapphire glass, phone screens, silicon wafers. Grinding of precision ceramic parts (bearing balls, nozzles). Profiling and polishing of stone, concrete. Sharpening of PCD and PCBN inserts.