Post RFQ

Post RFQ

Post RFQ

Post RFQ

Exceptional thermal stability (withstands >1400°C), maintaining strength and cutting ability at grinding temperatures, greatly reducing workpiece thermal damage (burn, cracks). Extremely low wear rate and superb wheel form retention, ideal for batch, high-precision production on CNC grinders.

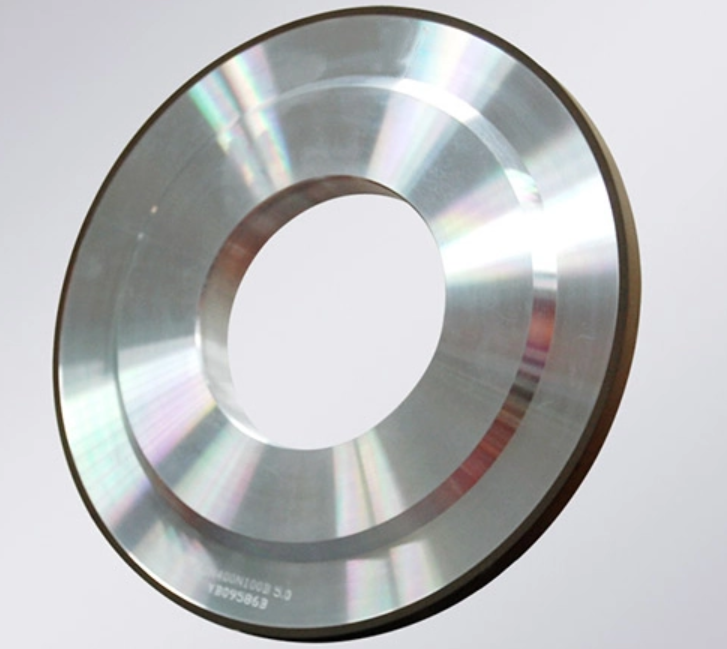

Typically consists of a steel or aluminum hub with an outer CBN abrasive layer. Bonds include electroplated (single layer), vitrified, or metal (multi-layer). Key parameter "concentration" indicates CBN content (100% concentration = 4.4 carats/cm³). Grit sizes from #120 to micron level. Requires rigid machine tools and ample coolant.

Precision grinding of automotive camshafts, crankshafts, gears; machining of high-temperature alloys in aerospace; sharpening and slot grinding of high-hardness complex tools (e.g., carbide end mills); superfinishing of precision bearing (P4/P2 class) raceways.