Post RFQ

Post RFQ

Post RFQ

Post RFQ

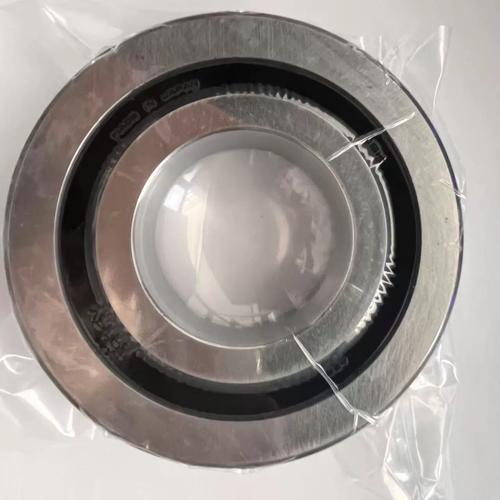

The design of this bearing focuses on enhancing high-speed performance and operational stability.Silicon nitride(Si3N4)ceramic balls have a density approximately 40%lower than steel balls,which can significantly reduce centrifugal force generated during high-speed rotation,thereby lowering pressure on the outer ring raceway and frictional heat.Ceramic material offers self-lubricating properties and better resistance to seizure under poor lubrication compared to steel.The polyimide cage maintains dimensional stability and strength at elevated temperatures.The bearing is typically used in conjunction with an oil-air lubrication system for optimal cooling.

The basic bearing designation is 6902,featuring a hybrid ceramic design.The steel rings are made from Japanese standard SUJ2(equivalent to GCr15),with a post-heat-treatment hardness above HRC 60.The rolling elements are G5 grade high-precision silicon nitride ceramic balls,characterized by high hardness(above HV 1500),low thermal expansion coefficient,and electrical insulation.The cage material is polyimide,capable of withstanding short-term peak temperatures up to 260°C.The bearing precision grade is typically ABEC-7(P4)or higher.Factory clearance is usually C2 or a specially designed small clearance group to accommodate preload requirements at high speeds.

Primarily used in spindle units with high demands for speed and precision,such as PCB drilling machine spindles,CNC engraving/milling machine motorized spindles,high-speed centrifuge rotor supports,dental handpieces,and high-speed shaft systems in some aerospace testing equipment.These applications often require stable bearing operation at tens of thousands of RPM with low temperature rise.