Post RFQ

Post RFQ

Post RFQ

Post RFQ

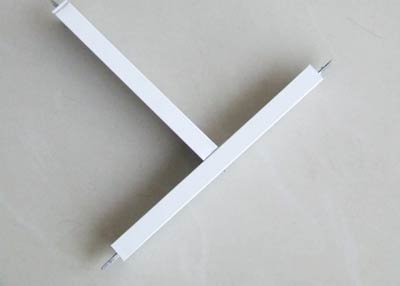

The coating on these products generally exhibits strong adhesion and some resistance to scratching.High-quality polyester or fluorocarbon coatings can provide good color consistency and UV resistance,potentially reducing fading risk under indoor lighting.The coated surface is smooth and easy to clean.As all surface finishing is completed at the factory,no secondary painting is required on-site,which can contribute to a cleaner job site and shorter project timelines.

Beyond the basic dimensional specs(height,width,thickness)which conform to regular standards,the core specifications relate to the coating system.This includes the coating type(a common combination is epoxy primer+polyester topcoat),dry film thickness,gloss level(matte,semi-gloss,gloss),and specific color codes.For areas requiring high weather resistance(e.g.,sunrooms),PVDF fluorocarbon coatings may be used,which are subject to more stringent performance standards like AAMA 2605.

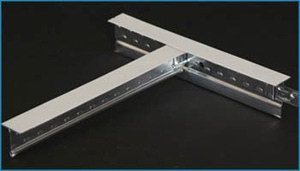

Primarily used in exposed grid ceiling systems where the grid is a visible visual component.Common in retail stores,cafes,restaurants,gymnasiums,and educational institutions where spatial aesthetics are emphasized.Designers can use main,furring,and wall angle joists in different colors to create decorative effects like patterns,lines,or borders.It is also suitable for areas with high cleanliness and hygiene requirements,such as food processing zones or laboratories,as its smooth painted surface can be less prone to dust accumulation and easier to wipe clean compared to a galvanized surface.